Service Management uses appointments and tasks to make creating service calls and scheduling technicians precise and flexible.

A task is assigned to a technician, scheduled, then completed as part of a service call. When tasks are commonly completed together, such as tasks that are completed sequentially as part of a routine maintenance visit, they can be grouped into lists. These lists can then be saved as a task list and easily selected in the future.

There are many benefits to using tasks and task lists:

-

Individual tasks can be assigned with an estimated time and required task materials. This helps generate accurate quotes in the Maintenance contract quote module. When combined in a task list, the hours and materials of all tasks in the list can be summed to give an accurate estimated time and forecasted cost for the entire call. This quote task list can later be copied to a service call or used to generate a maintenance contract. From there, it can be printed and used by the technician for clear instructions for the call.

-

One task can have multiple responses added. For example, if you are entering a reading for a tire inspection, you may need to record the tire brand, the type of tire, and the tread depth. Instead of having to create each of the responses as a separate task, you can now add all these responses to one task. You could also set up a repair type if the tire needs to be changed and another if the brake pad needs to be changed. Additionally, you can set up a response that will generate a service call based on the input.

-

You can print a task report that lists all tasks, subtasks, and materials for a call. Because materials can be assigned to tasks, a list of all materials needed for a service call can also be easily compiled before the appointment. This allows the scheduled technician to view the details of the service or maintenance call.

-

Task lists also provide a clear and easy way for technicians to log their progress and take notes on individual procedures. These notes can then be entered into the system so a careful record is kept of the work done and the current status for each task on the call.

-

Tasks can be set to a schedule so that they automatically generate service calls (MCC calls) and add them to your schedule/dispatch board. For example, as part of a maintenance contract, the equipment may come with a yearly tune-up. This tune-up may require tasks such as tightening all electrical connections or changing the oil. These and limitless other small tasks can be compiled into a task list, selected in the equipment or customer record, given an ANNUAL frequency, and assigned to the equipment. This will automatically schedule an annual "tune-up" appointment for a technician who is appropriate for the tasks and equipment involved. You can also skip a task's scheduled date(s) by unmarking the Required checkbox in the Maintenance Tasks window. See Assigning Tasks and Task Lists to Equipment for more information.

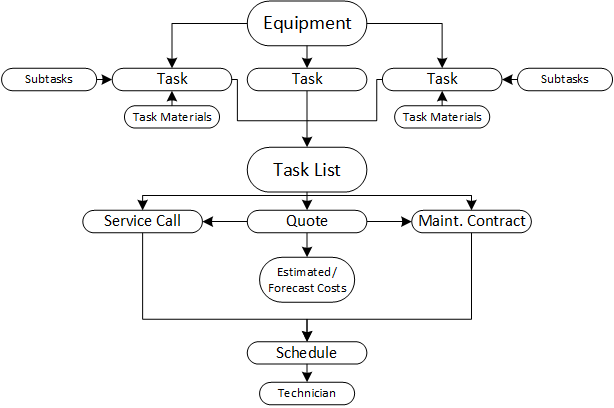

A piece of equipment may have one or more tasks assigned to it. These tasks may have subtasks and materials assigned to them. All the tasks associated with the piece of equipment may be combined to form a task list or multiple task lists.

Task lists can be selected to help organize quotes, maintenance contracts, or individual service calls for the equipment. Service calls may have tasks assigned to them directly if there is no equipment involved with the service, or in addition to what is already assigned to the equipment. Quote task lists are useful for estimating the time and expense required for a service or maintenance call. Quote task lists, as well as any other task lists, can be copied to create a new task list for a maintenance contract, a service call, or another quote. You must own the Maintenance Contract Quote module to create, add, or copy quote tasks and task lists.

Once tasks are created for a contract or a service call, they can be scheduled and assigned to a technician. Alternatively, contract tasks can be set to a schedule so that the system generates routine appointments (MCC calls) automatically.

Task codes and task lists can be inactivated on their respective setup windows. Proceed with caution when you mark a task code or task list inactive. Inactivating a task code will inactivate it throughout Service Management as well as Equipment Management. History will not be affected, nor will existing contracts, quotes, service calls, and or scheduled maintenance (Equipment Management).

When you inactive a task code, the following is true:

-

Inactive task codes and task lists are filtered out from displaying in any lookup and cannot be added to contracts, quotes, and/or service calls.

-

When a task code is marked inactive and already exists in a task list, the inactive task code is indicated with a red indicator.

-

When using hierarchy task lists, if a parent task is inactive, child tasks of that parent task are also inactive on the task list only. (Hierarchy child tasks are not automatically inactivated at the setup level.)

-

Existing contracts, quotes, and calls, that have task codes or task lists will not be affected by a task code or task list being marked inactive.

-

When renewing a contract (single, master, or mass), you can print a new Inactive Task or Task List report before renewing. If the contract has tasks that include inactive tasks and/or task lists, this report is automatically generated as well so that users can fix the data (reactivate the task code/task list or remove the inactive task codes or lists from the contract).

-

When creating a new contract using equipment at the location, if the equipment type has a task list associated and you choose to automatically add task codes based on equipment type, only the active task codes will be added to the contract.

-

In Equipment Management:

-

Existing scheduled maintenance that has task codes or task lists will not be affected by a task code or task list being marked inactive.

-

When creating a service call from the On Rental Entry and/or the Rental Agreement Line Entry windows, only active task codes in the Equipment Model task list are added to the service call. (This task list is assigned to the equipment model in the Equipment Model Maintenance window.)

-

When processing scheduled maintenance to create a service call, only active task codes assigned in the Scheduled Maintenance Type Setup window are added to the service call.

-

See also:

Children macro unable to render for apps.